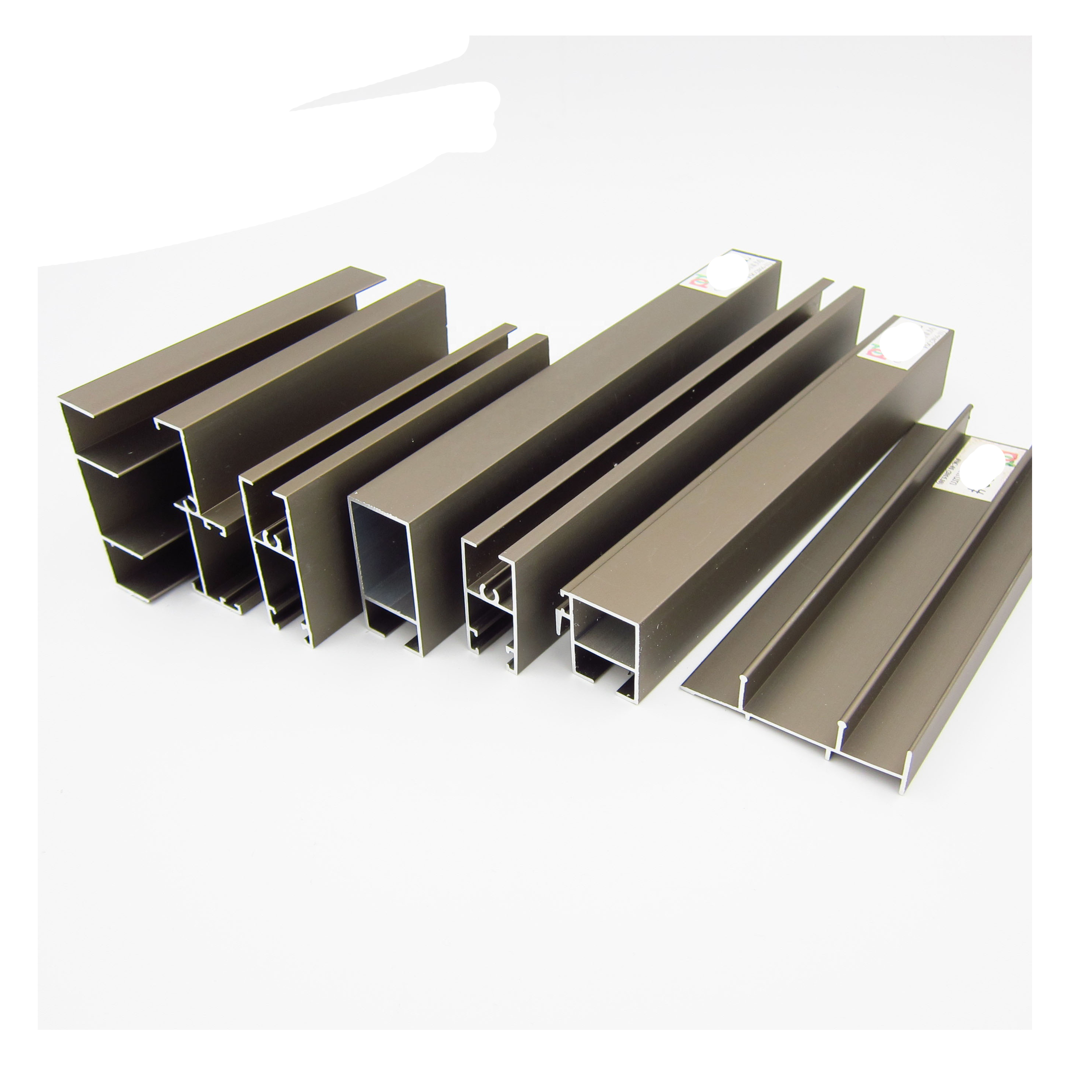

6063 Champagne Anodized Aluminum Window Profiles Extrusion

Basic Info

Model No.: YL 1235 series

Product Description

Profile Specification:

| Description | 6063 Champagne Anodized Aluminum Window Profiles Extrusion |

| Material Thickness(t) | 0.8-2.0 mm |

| Materiral | aluminum alloy 6063 |

| Annealing Treatment | T3-T8 |

| Color | Wood, Silver White ,Bronze , Champagne, Black,( 60678265, 60553536, 59954113,RAL series)etc. |

| Surface Treatment | anodized, powder coated, electrophoresis, wood grain, polished and etc |

| Shape | Square, Round, Flat, Oval, and according to customer's drawing. |

| Length | Normal length=6m or in customer's order |

| Usage | Building, Production Line, Decoration, Industrial, Transportation, Door and window, etc. |

| Package | 1. Pearl cotton foam for each profile; 2. Wrap with shrink film exterior; 3. Packed according to customer request. |

| Advantages/Features | Providing colorful products with various mechanical performances to adapt all kinds of architectural styles |

Aluminum Surfaces Description:

1.Sand blasting

The process of cleaning and roughening metal surface by using the impact of high-speed sand flow. The surface treatment of aluminum parts by this method can make the surface of the workpiece obtain certain cleanliness and different roughness, and improve the mechanical properties of the workpiece surface. Therefore, it improves the fatigue resistance of the workpiece, increases the adhesion between it and the coating, prolongs the durability of the coating film, and is also conducive to the leveling and decoration of the coating.

2. Polishing

Using mechanical, chemical or electrochemical methods to reduce the surface roughness of the workpiece, so as to obtain a bright and flat surface. Polishing process is mainly divided into: mechanical polishing, chemical polishing and electrolytic polishing. After mechanical polishing + electrolytic polishing, it can approach the stainless steel mirror effect, giving people the feeling of high-grade, simple and fashionable future (of course, it is easy to leave fingerprints, and more care should be taken).

3. Wire drawing

Wire drawing is the manufacturing process of repeatedly scraping aluminum plates out of lines with sandpaper. Wire drawing can be divided into straight wire drawing, random wire drawing, rotary wire drawing and thread drawing. The Metal Wire drawing process can clearly show each fine wire mark, so that the fine hair luster can be reflected in the metal matte. The product has a sense of fashion and science and technology.

4. High gloss cutting

The diamond knife is reinforced on the main shaft of the precision engraving machine with high-speed rotation (generally 20000 RPM) by the precision engraving machine to cut parts, resulting in local bright areas on the product surface. The brightness of cutting highlight is affected by the milling bit speed. The faster the bit speed is, the brighter the cutting highlight is. On the contrary, it is darker and easy to produce knife marks. High gloss cutting is especially used in mobile phones.

5. Anodizing

Anodizing refers to the electrochemical oxidation of metals or alloys. Aluminum and its alloys form an oxide film on aluminum products (anodes) under the action of external current under the corresponding electrolyte and specific process conditions. Anodizing can not only solve the defects of aluminum surface hardness and wear resistance, but also prolong the service life of aluminum and enhance the beauty. It has become an indispensable part of aluminum surface treatment. It is the most widely used and very successful process at present.

6. Two Color Anodizing

Two Color Anodizing refers to anodizing on a product and giving different colors to specific areas. The cost of two-color anodizing is high because of the complex process; However, through the comparison between two colors, it can better reflect the high-end and unique appearance of the product

Corporate Introdiction:

Guangdong Yong long Aluminum Co., Ltd. is located in the No. 10 (Sanjiang market) of Leping Town, Sanshui District, Foshan. The company was founded in 1997. It is a comprehensive and large-scale aluminum profile enterprise integrating the research and development, production and sales of aluminum alloy profiles. The company is leading the "Hong Ying" brand. Strong comprehensive strength and excellent service make Yong long "Hong Ying" sell well all over the country and exported to Southeast Asia, Europe, South America and many other countries.

The company has 900 employees, including 120 high and intermediate engineering technology and management personnel, with advanced and perfect design, production, testing and testing methods as well as perfect sales network and after-sales service system. The products sell well in more than 10 national and foreign ports, Australia and Taiwan areas.

1.20 years' experience and advanced equipment

2.Customize: We can manufacture according to your size and shape of such aluminum profile;

3.Strong production capacity - 28 extrusion lines, 50,000TONS/Year

4.One Stop Service Specialized in mould, extrusion, anodizing, powder coating, wood grain and Processing;

5.Shortest Delivery , competitive prices and excellent service

Product Photos:

Product Categories : Aluminum Profiles > Anodized Aluminum Prfoiles